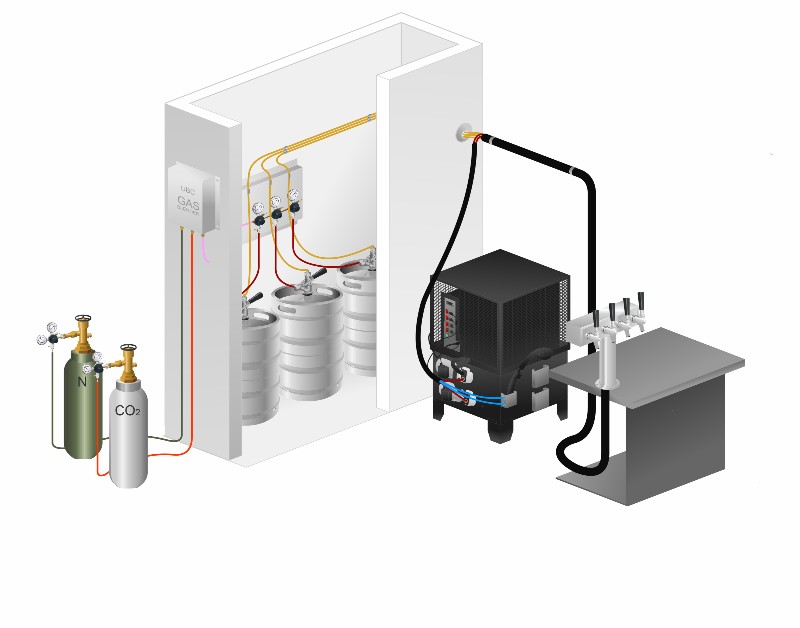

The refrigeration system is used for mashing wort cooling and fermentation cooling. After the optimized design of the refrigeration system, the energy consumption in the operation of the brewery equipment is reduced. The refrigeration system mainly includes refrigeration units and ice water tanks.

1: The refrigerator is used for cooling and cooling in the beer brewing process. The water temperature is adjusted and controlled within the range of -5°C to 5°C to provide a steady stream of cooling water for beer brewing.

Professional refrigerator:

- Equipped with an open stainless steel thick incubator, built-in automatic water replenishment and automatic temperature control;

- Low temperature screw chiller;

- Compressor, built-in safety protection;

- The condenser adopts the casing type, internal thread copper pipe;

- Stainless steel shell, corrosion resistance;

- Equipped with stainless steel water pump;

- High heat exchange efficiency and good heat dissipation performance;

- High efficiency and low noise;

- Power saving and durable, long service life;

- Install casters, easy to move.

Two: The ice water tank is used to prepare ice water for fermentation cooling and cooling water cooling.

Professional ice water tank:

- The raw material is sanitary stainless steel 304/306L;

- Polyurethane insulation thickness 100mm;

- Equipped with a temperature probe (PT100).

- Daily maintenance of ice water tank and refrigerator.

1: Maintenance of ice water tank.

The ice water tank has a liquid level. We make a mark on the liquid level pipe to know the volume of the refrigerant in the tank. After a long time, when the liquid level drops, we need to add the corresponding 95% alcohol to supplement the lost alcohol to meet our needs. concentration, cooling effect. The pipeline between the ice water tank and the ice water pump should be tightened frequently to prevent leakage.

2: Daily maintenance of the refrigerator.

①Copper tube refrigerator, mainly check the high pressure gauge and low pressure gauge of the refrigerator. The refrigerator has pressure control. If the pressure is too low, the refrigerator will not start, and if the pressure is too high, it will not start. The copper pipe nut should be tightened accordingly after a long time to prevent the leakage of fluorine. The refrigerator has three live wires, one neutral wire and one ground wire, and the terminals should also be tightened.

② Keep the host clean.

③Check whether the parts of the main engine are loose or damaged.

④Check whether there is refrigerant leakage, check whether the pressure of the pressure gauge is 0, or whether there is a drop from the usual reading value. To check the leakage, you can visually check whether there is oil stains or refrigerant leakage at the connection of each pipeline or the assembly of parts. , And with soapy water or refrigerant leak detector to confirm whether there is leakage.

⑤Check whether the water temperature, water pressure and water flow of the external interlock circuit, flow switch and water pipeline are normal, and whether they have been completely exhausted.

⑥Check whether the power supply is normal before and after starting the machine.

⑦ After starting the machine, check whether there is abnormal vibration and noise.

⑧ After starting the machine, check whether the high and low pressures are normal.

⑨ After the machine is turned on, check whether the operating conditions of the main engine such as starting, stopping, and temperature control are normal.

⑩Record the operation status of the main engine; voltage, current, high and low pressure, temperature and pressure of the inlet and outlet water of the condenser and evaporator. The lubricating oil in the compressor has been installed during the production of the main engine, so it does not need to be filled again. It should be supplemented only when the unit is dismantled and repaired. When the unit is in abnormal condition, professional technicians should be notified for overhaul.